Chinhu chakagadzirwa nesimbi yakaoma inogadziriswa nesimbi inosunga nesimbi inosunga kuburikidza nekugadzirwa kwesimbi yeupfu. Carbide yakagadzirwa nesimende ine zvinhu zvakawanda zvakanaka zvakaita sekuomarara kwakanyanya, kusakara, simba rakanaka uye kusimba, kusapisa uye kuramba ngura, kunyanya kuomarara kwayo kwakanyanya uye kusakara, izvo zvinoramba zvisina kuchinja kunyangwe patembiricha ye500 °C, ichiri nekuomarara kwakanyanya pa1000℃. Carbide inoshandiswa zvakanyanya semidziyo yekushandisa, senge maturusi ekutenderedza, zvigayo zvekucheka, maplaner, madrill, maturusi anoboorera, nezvimwewo, pakucheka simbi yakakandwa, simbi dzisina ferrous, mapurasitiki, makemikari fibers, graphite, girazi, matombo nesimbi yakajairika, uye inogonawo kushandiswa pakucheka zvinhu zvakaoma kushandisa muchina zvakaita sesimbi isingapisi, simbi isina ngura, simbi ine manganese akawanda, simbi yekushandisa, nezvimwewo. Kumhanya kwekucheka kwemidziyo mitsva yecarbide ikozvino kwakapetwa mazana esimbi yekabhoni.

Kushandiswa kwecarbide yakagadzirwa nesimende

(1) Zvishandiso

Carbide ndiyo yakawanda yezvinhu zvekushandisa, zvinogona kushandiswa kugadzira maturusi ekutenderedza, zvigayo zvekucheka, mapuraneri, mabhora, nezvimwewo. Pakati pazvo, tungsten-cobalt carbide yakakodzera kugadzirwa kwechip pfupi chesimbi dzesimbi dzisina simbi uye kugadziriswa kwezvinhu zvisiri zvesimbi, zvakaita sesimbi yakakandwa, simbi yakakandwa, bakelite, nezvimwewo; tungsten-titanium-cobalt carbide yakakodzera kugadzirwa kwenguva refu kwesimbi dzine simbi dzakadai sesimbi. Kugadzira chip. Pakati pema alloys akafanana, ayo ane cobalt yakawanda akakodzera kugadzirwa kwe rough machining, uye ayo ane cobalt shoma akakodzera kupedzwa. Carbides dzakagadzirwa nesimende dzinoshanda kwenguva yakareba kupfuura mamwe ma carbides akasimwa emidziyo yakaoma kushandisa muchina yakadai sesimbi isina ngura.

(2) Zvinhu zvekuumba

Carbide yakagadzirwa nesimende inonyanya kushandiswa pakugadzira zvinhu zvinotonhora zvakaita sema "cold drawing dies", "cold punching dies", "cold extrusion dies", uye "cold pier dies".

Madhayi eCarbide anodiwa kuti ave nekusimba kwakanaka kwekukanda, kusimba kwekupwanyika, simba rekuneta, simba rekukotama uye kuramba kupfeka zvakanaka mumamiriro ekushanda asingatsvedzeri kana kusimba. Magiredhi epakati nepakati neakakwirira ecobalt uye epakati nepakati nepakati anowanzo shandiswa, akadai seYG15C.

Kazhinji, hukama huripo pakati pekusapera uye kusimba kwecarbide yakagadzirwa nesimende hunopesana: kuwedzera kwekusapera kuchaita kuti kusimba kuve kushoma, uye kuwedzera kwekusimba kuchaita kuti kusimba kuve kushoma. Saka, pakusarudza magiredhi e alloy, zvakakosha kusangana nezvinodiwa zvekushandisa zvichienderana nechinhu chekugadzirisa uye mamiriro ekushanda ekugadzirisa.

Kana giredhi rakasarudzwa richikurumidza kutsemuka nekukuvadzwa panguva yekushandiswa, giredhi rine kusimba kwakanyanya rinofanira kusarudzwa; kana giredhi rakasarudzwa richikurumidza kusakara nekukuvadzwa panguva yekushandiswa, giredhi rine kusimba kwakanyanya uye kuramba kupfeka kuri nani rinofanira kusarudzwa. . Magiredhi anotevera: YG15C, YG18C, YG20C, YL60, YG22C, YG25C Kubva kuruboshwe kuenda kurudyi, kuomarara kunoderera, kuramba kupfeka kunoderera, uye kusimba kunowedzera; pane zvinopesana, zvakapesana ndizvo zvazviri.

(3) Zvishandiso zvekuyera uye zvikamu zvisingapfeki

Carbide inoshandiswa pakuisa zvinhu zvisingapfeki pamusoro uye pazvikamu zvezvishandiso zvekuyera, mabheyaringi akarurama emagrinder, maplate ekutungamira uye tsvimbo dzinotungamira dzemagrinder asina pakati, pamusoro pemachira ekugadzira uye zvimwe zvikamu zvinodzivirira kupfekwa.

Zvisimbi zvebinder zvinowanzova simbi dzeboka resimbi, dzinowanzova cobalt nenickel.

Pakugadzira carbide yakagadzirwa nesimende, saizi yezvikamu zveupfu hwezvinhu zvakasarurwa iri pakati pe1 ne2 microns, uye kuchena kwacho kwakanyanya. Zvinhu zvakasarurwa zvinosanganiswa zvichienderana nehuwandu hwakatarwa hwekuumbwa, uye doro kana zvimwe zvinhu zvinowedzerwa pakukuya zvakanyorova mugayo rebhora rakanyorova kuti zvisanganiswe zvizere uye zvikuyiwe. Sefa musanganiswa. Zvadaro, musanganiswa wacho unopwanywa, wodzvanywa, uye wodziiswa kusvika patembiricha iri pedyo nenzvimbo yekunyunguduka kwesimbi yesimbi (1300-1500 °C), chikamu chakaomeswa nesimbi yesimbi yesimbi zvinoumba eutectic alloy. Mushure mekutonhora, zvikamu zvakaomeswa zvinogoverwa mugrid yakagadzirwa nesimbi yekubatanidza uye zvakabatana zvakanyanya kuti zvigadzire chinhu chakasimba. Kuoma kwecarbide yakagadzirwa nesimende kunoenderana nehuwandu hwechikamu chakaomeswa nehukuru hwezviyo, kureva kuti, huwandu hwechikamu chakaomeswa uye tsanga dzakatetepa, kuoma kwacho kunowedzera. Kuoma kwecarbide yakagadzirwa nesimende kunotsanangurwa nesimbi yesimbi yesimbi. Kana huwandu hwesimbi yesimbi yesimbi hwakakwira, simba reflexural rakawedzera.

Muna 1923, Schlerter wekuGermany akawedzera 10% kusvika 20% ye cobalt ku tungsten carbide powder se binder, uye akagadzira alloy itsva ye tungsten carbide ne cobalt. Kuoma kwayo kwakatevera dhaimani chete. Carbide yekutanga yakagadzirwa ne simende. Pakucheka simbi nechishandiso chakagadzirwa ne alloy iyi, mucheto wekucheka uchapera nekukurumidza, uye kunyange mucheto wekucheka uchatsemuka. Muna 1929, Schwarzkov muUnited States akawedzera huwandu hwakati hwe tungsten carbide ne titanium carbide compound carbides kune zvakaumbwa pakutanga, izvo zvakavandudza mashandiro echishandiso pakucheka simbi. Uku ndiko kumwe kubudirira munhoroondo yekugadzirwa kwe cemented carbide.

Carbide yakagadzirwa nesimende ine zvinhu zvakawanda zvakanaka zvakaita sekuomarara kwakanyanya, kusakara, simba rakanaka uye kusimba, kusapisa uye kuramba ngura, kunyanya kuomarara kwayo kwakanyanya uye kusakara, izvo zvinoramba zvisina kuchinja kunyangwe patembiricha ye500 °C, zvichiri nekuomarara kwakanyanya pa1000℃. Carbide inoshandiswa zvakanyanya semidziyo yekushandisa, senge maturusi ekutenderedza, zvigayo zvekucheka, maplaner, madhiri, maturusi anoboorera, nezvimwewo, pakucheka simbi yakakandwa, simbi dzisina ferrous, mapurasitiki, makemikari fibers, graphite, girazi, matombo nesimbi yakajairika, uye inogonawo kushandiswa pakucheka zvinhu zvakaoma kushandisa muchina zvakaita sesimbi isingapisi, simbi isina ngura, simbi ine manganese akawanda, simbi yezvishandiso, nezvimwewo. Kumhanya kwekucheka kwezvishandiso zvitsva zvecarbide ikozvino kwakapetwa mazana esimbi yekabhoni.

Carbide inogona kushandiswawo kugadzira maturusi ekuchera matombo, maturusi ekuchera, maturusi ekuchera, maturusi ekuyera, zvikamu zvisingapfeki, masimbi anobvisa simba, ma cylinder liners, ma precision bearing, ma nozzles, ma mold esimbi (akadai se wire drawing dies, bolt dies, nut dies, uye ma fastener mold akasiyana-siyana, kushanda kwakanaka kwe cemented carbide kwakatsiva zvishoma nezvishoma ma mold esimbi ekare).

Gare gare, carbide yakagadzirwa nesimende yakabudawo. Muna 1969, Sweden yakabudirira kugadzira chishandiso chakagadzirwa netitanium carbide. Hwaro hwechishandiso i tungsten-titanium-cobalt carbide kana tungsten-cobalt carbide. Ukobvu hwetitanium carbide coating pamusoro i microns shoma chete, asi kana ichienzaniswa nerudzi rumwe chete rwezvishandiso zve alloy, Hupenyu hwebasa hunowedzerwa katatu, uye kumhanya kwekucheka kunowedzerwa ne25% kusvika 50%. Muma1970, chizvarwa chechina chezvishandiso zvakafukidzwa chakaonekwa chekucheka zvinhu zvakaoma kushandisa muchina.

Carbide yakagadzirwa nesimende inopiswa sei?

Carbide yakagadzirwa nesimende isimbi inogadzirwa nesimbi inogadzirwa nesimbi inogadzirwa neupfu inogadzirwa nesimbi dzinosungirirwa kubva musimbi imwe chete kana kupfuura dzinoramba kushandiswa.

Mnyika dzinogadzira zvinhu

Kune nyika dzinopfuura makumi mashanu pasi rose dzinogadzira carbide yakagadzirwa nesimende, ine huwandu hwe27,000-28,000t-. Vagadziri vakuru ndiUnited States, Russia, Sweden, China, Germany, Japan, United Kingdom, France, nezvimwewo. Musika wecarbide yakagadzirwa nesimende pasi rose wakazara. , makwikwi emusika akanyanya. Indasitiri yecarbide yakagadzirwa nesimende muChina yakatanga kuoneka mukupera kwema1950. Kubva kuma1960 kusvika kuma1970, indasitiri yecarbide yakagadzirwa nesimende muChina yakawedzera nekukurumidza. Mukutanga kwema1990, kugona kwese kwekugadzira carbide yakagadzirwa nesimende muChina kwakasvika 6000t, uye huwandu hwese hwecarbide yakagadzirwa nesimende hwakasvika 5000t, yechipiri chete muRussia neUnited States, iri panhamba yechitatu pasi rose.

Mucheka weWC

①Tungsten necobalt carbide yakagadzirwa nesimende

Zvikamu zvikuru i tungsten carbide (WC) uye binder cobalt (Co).

Rudzi rwayo rwunoumbwa ne "YG" ("yakaoma uye cobalt" muchiChinese Pinyin) uye huwandu hweavhareji yehuwandu hwe cobalt.

Semuenzaniso, YG8 zvinoreva avhareji yeWCo=8%, uye yasara i tungsten-cobalt carbide ye tungsten carbide.

Mapanga eTIC

②Tungsten-titanium-cobalt carbide

Zvikamu zvikuru i tungsten carbide, titanium carbide (TiC) uye cobalt.

Rudzi rwayo rwune mavara maviri ekuti “YT” (“hard, titanium” muchiChinese Pinyin prefix) uye avhareji yehuwandu hwetitanium carbide.

Semuenzaniso, YT15 zvinoreva avhareji yeWTi=15%, uye yasara i tungsten carbide uye tungsten-titanium-cobalt carbide ine cobalt yakawanda.

Chishandiso cheTungsten Titanium Tantalum

③Tungsten-titanium-tantalum (niobium) carbide yakagadzirwa nesimende

Zvikamu zvikuru i tungsten carbide, titanium carbide, tantalum carbide (kana niobium carbide) uye cobalt. Rudzi urwu rwe cemented carbide runonziwo general cemented carbide kana universal cemented carbide.

Giredhi rayo rinoumbwa ne "YW" (chivakashure chefonetiki chechiChinese che "hard" uye "wan") pamwe nenhamba yekutevedzana, senge YW1.

Hunhu hwekushanda

Carbide Welded Inserts

Kuomarara kwakanyanya (86 ~93HRA, yakaenzana ne69 ~81HRC);

Kuomarara kwakanaka kwekupisa (kusvika 900 ~1000 ℃, chengeta 60HRC);

Kudzivirira kukwenya kwakanaka.

Zvishandiso zvekucheka kabhidhibhi zvinokurumidza ka4 kusvika ka7 kupfuura simbi inomhanya zvakanyanya, uye hupenyu hwezvishandiso hwakawedzera ka5 kusvika ka80. Pakugadzira maforoma nezvishandiso zvekuyera, hupenyu hwebasa hwakawedzera ka20 kusvika ka150 kupfuura hwesimbi yesimbi ye alloy. Inogona kucheka zvinhu zvakaoma zve50HRC.

Zvisinei, kabhidhidhi yakasimbiswa haina kusimba uye haigone kushandiswa muchina, uye zvakaoma kugadzira maturusi akabatana ane maumbirwo akaomarara. Nokudaro, mapanga emhando dzakasiyana anowanzogadzirwa, ayo anoiswa pamuviri wezvishandiso kana muviri weforoma nekusanganisa, kusungirira, kusungira michina, nezvimwewo.

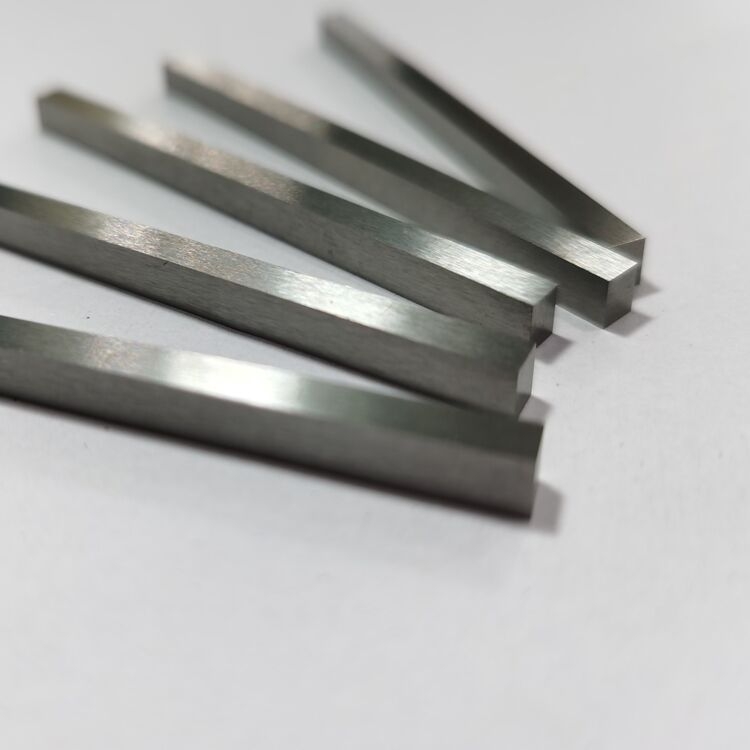

Bhawa rakaita serakasiyana

Kupisa

Kuumba sintering yekabhoyidi yakagadzirwa nesimbi kunosanganisira kudzvanya upfu mu billet, wobva wapinda muchoto chinopisa kusvika patembiricha yakatarwa (sintering tembiricha), wochichengeta kwenguva yakati (munguva yakatarwa), wozochitonhodza kuti uwane simentary carbide ine hunhu hunodiwa.

Maitiro ekupisa simende yekabhonidhi anogona kukamurwa kuita zvikamu zvina zvikuru:

1: Padanho rekubvisa chinhu chinoumba uye pre-spring, muviri wakacheneswa unoshanduka seizvi:

Kubviswa kwechinhu chinoumba, nekuwedzera kwekupisa pakutanga kwekusviba, chinhu chinoumba chinoora zvishoma nezvishoma kana kupwanyika, uye muviri unosviba unobviswa. Rudzi, huwandu uye maitiro ekusviba zvakasiyana.

Ma oxide ari pamusoro peupfu anodzikira. Pakupisa kwekusviba, hydrogen inogona kuderedza ma oxide e cobalt ne tungsten. Kana chinhu chinoumba chikabviswa mu vacuum uye chakasviba, carbon-oxygen reaction haina kusimba. Kusangana pakati pezvikamu zveupfu kunobviswa zvishoma nezvishoma, upfu hwesimbi hunobatana hunotanga kupora uye kudzokororwa, kupararira kwepasi kunotanga kuitika, uye simba re briquetting rinovandudzika.

2: Danho rekupisa kwechikamu chakasimba (800℃–eutectic tembiricha)

Pakupisa kusati kwaonekwa chikamu chemvura, pamusoro pekuenderera mberi kwekuita kwechikamu chekare, maitiro echikamu chakasimba uye kupararira zvinowedzerwa, kuyerera kwepurasitiki kunowedzerwa, uye muviri wakacheneswa unodzikira zvakanyanya.

3: Danho rekupisa mvura (tembiricha ye eutectic - tembiricha yekupisa)

Kana chikamu chemvura chikaonekwa mumuviri wakacheneswa, kupwanyika kwacho kunopera nekukurumidza, zvichiteverwa nekushandurwa kwekristalographic kuti kugadzire chimiro chekutanga uye chimiro chealloy.

4: Danho rekutonhodza (tembiricha yekudziya - tembiricha yemukamuri)

Padanho rino, chimiro uye chimiro chechikamu che alloy zvine shanduko dzakasiyana nemamiriro ekutonhodza. Chinhu ichi chinogona kushandiswa kupisa carbide yakagadzirwa nesimende kuti ivandudze hunhu hwayo hwepanyama uye hwemakanika.

Nguva yekutumira: Kubvumbi-11-2022