Kusapfeka kwakanaka kwazvotungsten carbide mashizha, kunyange zvazvo iri nani pane zvimwe zvinhu zvakawanda zvekucheka, inogona kuora zvishoma nezvishoma kuburikidza nenzira dzakawanda panguva imwe chete kana ichishanda nguva dzose kwenguva yakareba. Kunzwisisa maitiro aya ekupfekwa kwakakosha pakugadzira nzira dzinoshanda dzekudzivirira uye kugadzirisa mashandiro emapanga mumaindasitiri.

1. Kupfeka Zvisina Kunaka

Kupfeka zvinogumbura kunomiririra imwe yenzira dzakajairika uye dzakakosha dzehupfumi dzinokanganisatungsten carbide mashizhamukushanda nguva dzose. Maitiro aya anoitika kana zvinhu zvakaoma kana zvidimbu zvakaoma zviri muchinhu chebasa zvikabatana nepamusoro pebanga, zvichikonzera kubviswa kwechinhu zvishoma nezvishoma kuburikidza nekucheka nekugadzira zvidimbu zvidiki. Kuoma kwakanyanya kwechinhu ichitungsten carbide tsangainopa simba guru pakupfeka uku, asi chikamu che cobalt binder chakapfava chinowanzo kanganiswa nekukweshwa, zvichikonzera kubuda kwe WC grains uye kutyoka kana kudhonzwa kwadzo. Tsvagiridzo inoratidza kuti kupfeka kwekukweshwa kunonyanya kuitika kana zvinhu zvekugadzira zvine zvinhu zvinokweshwa zvakaita se silicon-aluminium alloys, zvinhu zvinosanganiswa, kana workpieces dzine scales dzakaoma.

Mwero wekupfekwa kwesimbi unokonzerwa nezvinhu zvakasiyana-siyana, zvinosanganisira saizi uye chimiro chesimbi dzinopfekwa, hunhu hwebasa nesimbi, uye mamiriro ekucheka anoshandiswa. Zvakaonekwa mumaindasitiri zvinosimbisa kuti kupfeka kwesimbi kunowanzoonekwa sekupfekwa kwakafanana kwechiso chesimbi kana kugadzirwa kwemitsara iri pamusoro pechip-contact, uye mwero wekupfekwa unowanzoenderana zvakananga nedaro rekucheka uye zvinopesana nekuomarara kwekucheka.

2. Kupfeka Kunopararira

Kupera kwedhiraini, kunozivikanwawo sekupera kwedhiraini, kunonyanya kukosha mukushandiswa kwemashini ekupisa kwakanyanya uko tembiricha dzekucheka dzinodarika 800°C. Pakupisa uku kwakakwirira, makemikari ari mubhara retungsten carbide nesimbi yekushanda anowedzera kufamba, zvichikonzera kupararira kwese kwese pakati pemidziyo yekushanda. Chiitiko ichi chinonyanya kuoneka pakugadzira zvinhu zveferrous, uko simbi kubva pasimbi yekushanda inogona kupararira mubhara recarbide ukuwo kabhoni, tungsten, uye cobalt kubva pasimbi zvichipararira musimbi yedhiraini.

Maitiro ekupararira kwesimbi anochinja zvakanyanya maumbirwo uye hunhu hwezvikamu zvesimbi pamusoro pesimbi. Sezvo maatomu ekabhoni achifamba kubva pamusoro pesimbi, makristaro eWC anova asina kugadzikana, zvichikonzera kudzikira kwekuoma kwesimbi uye kusimba kwemuchina. Panguva imwe chete, kupararira kwecobalt kunoderedza kubatana pakati petungsten carbide grains, zvichikanganisa kugadzikana kwesimbi. Kuora kwemakemikari uku kunowanzo kukonzera kuumbwa kwekupfeka kwecrater pachiso cherake yesimbi, nekudzika kwakanyanya kwekupfeka kuchiitika panzvimbo yekupisa kwakanyanya. Zvidzidzo zvakaratidza kuti kuisa titanium carbide (TiC) muchimiro chetungsten carbide kunogona kuderedza zvakanyanya kupera kwesimbi nekuda kwekusakwana kweTiC kana tichienzanisa neWC uye kugona kwayo kugadzira zvikamu zvetitanium oxide zvinodzivirira pakupisa kwakakwira.

3. Kupfeka Zvinonamira uye Makemikari

Kupera kwe namatidziro kunoitika kana zvidimbu zvechinhu chebasa zvikasungirirwa pamusoro pebanga zvichibatanidzwa nekumanikidzwa kwakanyanya uye tembiricha panzvimbo yechinhu chinoshandiswa ne tool-workpiece. Makuno aya e namatidziro anogona kutyoka panguva yekufamba, zvichikonzera kubviswa kwezvidimbu zvidiki kubva pamusoro pebanga. Maitiro aya anonyanya kuitika pakugadzira zvinhu zvine ductile zvinowanzo namatira.maturusi ekucheka, zvakaita searuminiyamu alloys kana mamwe masimbi asina ngura.

Panguva imwe chete, maitiro ekupfeka makemikari, kusanganisira oxidation nezvimwe zvinoitwa ne thermochemical, zvinogona kubatsira zvakanyanya mukuora kwemapfundo, kunyanya munzvimbo dzinopisa zvakanyanya.Tungsten kabhayidhiinogona kuoxida kuti igadzire tungsten oxide necarbon dioxide patembiricha inodarika 600°C, nepo cobalt binder material inogonawo kuoxidation, zvichikonzera kuparara kwechikamu chebinder cheblade uye kurasikirwa kwetungsten carbide grains. Kuvapo kwemamwe machemical elements mu workpiece materials, akadai se chlorine kana sarufa mune mamwe ma alloys, kunogona kukurumidzisa maitiro aya ekupfeka makemikari kuburikidza nekuumbwa kwe volatile kana low-strength reaction products.

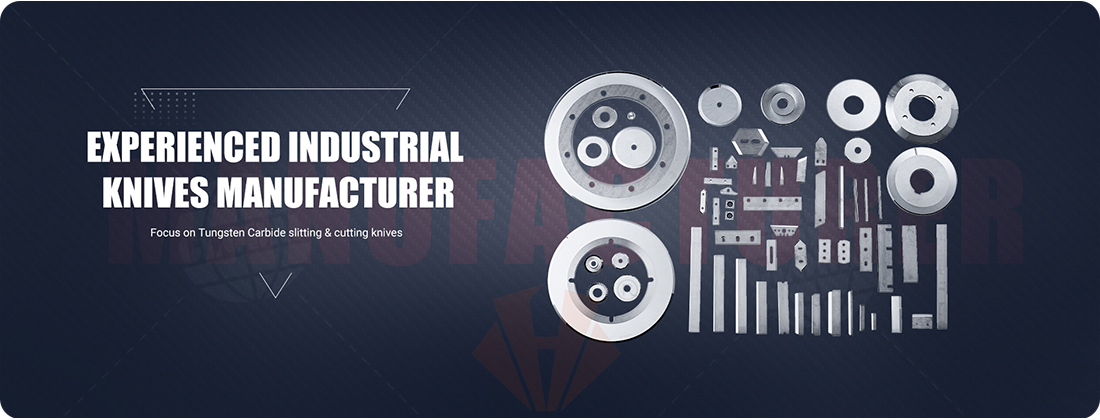

Nezve Huaxin: Tungsten Carbide Cemented Slitting Mapanga Mugadziri

CHENGDU HUAXIN CEMENTED CARBIDE CO., LTD inyanzvi mupi wezvigadzirwa zve tungsten carbide, zvakaita semapanga ekugadzira matanda e carbide, mapanga e carbide denderedzwa ekuchekerera matanda efodya nefodya, mapanga akatenderera ekuchekerera makadhibhodhi ane corugat, mapanga e razor ane maburi matatu/mashizha ane maburi ekurongedza, tepi, kucheka firimu rakatetepa, mapanga ekucheka fiber eindasitiri yemachira nezvimwewo.

Nemakore anopfuura makumi maviri nemashanu ekuvandudzwa, zvigadzirwa zvedu zvakatumirwa kuUS A, Russia, South America, India, Turkey, Pakistan, Australia, Southeast Asia nezvimwewo. Nemhando yepamusoro uye mitengo inokwikwidzana, maitiro edu ekushanda nesimba uye kupindura zvinotenderwa nevatengi vedu. Uye tinoda kutanga hukama hutsva hwebhizinesi nevatengi vatsva.

Taura nesu nhasi uye muchanakidzwa nemabhenefiti emhando yepamusoro uye masevhisi kubva kuzvigadzirwa zvedu!

Zvigadzirwa zvemabhurazi emumaindasitiri etungsten carbide zvinoshanda zvakanyanya

Sevhisi Yekugashira

Huaxin Cemented Carbide inogadzira tungsten carbide blades yakagadzirwa, mablanks akachinjwa uye akajairwa, kutanga kubva paupfu kusvika pablanks dzakapedzwa. Sarudzo yedu yakazara yemagiredhi uye maitiro edu ekugadzira anogara achipa maturusi anoshanda uye akavimbika ane chimiro chepedyo anotarisana nematambudziko ekushandiswa kwevatengi mumaindasitiri akasiyana-siyana.

Mhinduro Dzakagadzirirwa Maindasitiri Ese

mapanga akagadzirwa nemaoko

Mugadziri anotungamira wemashizha emaindasitiri

Mibvunzo inowanzo bvunzwa nevatengi uye mhinduro dzeHuaxin

Izvi zvinoenderana nehuwandu, kazhinji mazuva mashanu kusvika gumi nemana. Semugadziri wemabhura emumaindasitiri, Huaxin Cement Carbide inoronga kugadzirwa kwayo nemirairo nezvikumbiro zvevatengi.

Kazhinji mavhiki matatu kusvika matanhatu, kana ukakumbira mapanga emuchina akagadzirwa kana mapanga emuindasitiri asipo panguva yekutenga. Tsvaga Sollex Purchase & Delivery Conditions pano.

kana ukakumbira mapanga emuchina akagadzirwa nemaoko kana mapanga emuindasitiri asipo panguva yekutenga. Tsvaga Sollex Purchase & Delivery Conditionspano.

Kazhinji T/T, Western Union...dhipoziti yekutanga, Maodha ese ekutanga kubva kuvatengi vatsva anobhadharwa kare. Mamwe maodha anogona kubhadharwa ne invoice...taura nesukuziva zvakawanda

Ehe, taura nesu, mapanga emuindasitiri anowanikwa mumhando dzakasiyana-siyana, kusanganisira mapanga epamusoro, mapanga edenderedzwa epasi, mapanga ane serrated / tooth, mapanga anoboora akatenderera, mapanga akatwasuka, mapanga eguillotine, mapanga akapinza, mapanga erectangular razor, uye mapanga etrapezoidal.

Kuti tikubatsire kuwana banga rakanakisisa, Huaxin Cement Carbide inogona kukupa mienzaniso yakawanda yemashizha ekuyedza mukugadzirwa. Pakucheka nekushandura zvinhu zvinochinjika senge purasitiki, foil, vinyl, bepa, nezvimwewo, tinopa mapanga ekushandura anosanganisira mapanga ane mitsetse uye mapanga erazor ane mitsetse mitatu. Titumirei mubvunzo kana muchifarira mapanga emuchina, uye tichakupai chipo. Sampuli dzemapanga akagadzirwa nemaoko hadzipo asi munogamuchirwa kuodha huwandu hushoma hweodha.

Kune nzira dzakawanda dzinowedzera nguva yekubika mapanga nemapadza ako emuchina uye mapanga aripo. Tibatei kuti muzive kuti kurongedza kwakakodzera mapanga emuchina, mamiriro ekuchengetera, hunyoro uye tembiricha yemhepo, uye mamwe machira ekudzivirira mapanga enyu uye kuchengetedza kushanda kwawo pakucheka.

Nguva yekutumira: Gumiguru-24-2025