Mabhandi eCarbide anogadzirwa sei?

Mabanga eCarbide anokosheswa nekuda kwekuoma kwawo kwakanyanya, kuramba kupera, uye kugona kuchengetedza kupinza kwenguva yakareba, zvichiita kuti ave akakodzera kucheka zvinhu zvakasimba.

Mabanga eCarbide anowanzogadzirwa achishandisa nzira inosanganisira kunyungudutsa tungsten carbide powder kuita chimiro chakasimba, zvichiteverwa nekuumba uye kupedzisa banga. Heino pfupiso yemaitiro anowanzoitwa mabanga eCarbide:

1. Kugadzirira Zvinhu Zvisina Kugadzirwa

- Tungsten CarbideUpfu: Chinhu chikuru chinoshandiswa mumashizha ecarbide i tungsten carbide (WC), inova musanganiswa wakaoma uye wakakora we tungsten nekabhoni. Hupfu hwetungsten carbide hunosanganiswa nesimbi inosunga, inowanzova cobalt (Co), kuti ibatsire pakuita kuti sintering iite.

- Kusanganisa Upfu: Upfu hwetungsten carbide necobalt zvinosanganiswa pamwechete kuti zvigadzire musanganiswa wakafanana. Musanganiswa wacho unodzorwa nokungwarira kuti uve nechokwadi chekuti jira racho rakagadzirwa zvakanaka kuti rive rakaomarara uye rakasimba.

2. Kudzvanya

- Kuumba: Musanganiswa weupfu unoiswa muforoma kana die wodzvanywa kuita chimiro chakamanikana, chinova chimiro chakamanikana chebanga. Izvi zvinowanzoitwa pasi pekumanikidzwa kwakanyanya munzira inonzikudzvanya kwechando kunotsinzina (CIP) or kudzvanya kweyuniaxial.

- Kuumba: Pakudzvanya, chimiro chebanga chinoumbwa, asi hachisati chanyatsosimba kana kuti chakaoma. Chinodzvanya chinobatsira kusanganisa musanganiswa wehupfu kuti uite sechimiro chaunoda, senge chimiro chechishandiso chekucheka kana banga.

3. Kupisa

- Kupisa Kwekupisa Kwakanyanya: Mushure mekudzvanya, banga rinopiswa. Izvi zvinosanganisira kupisa chimiro chakadzvanywa muchoto patembiricha iri pakati pe1,400°C uye 1,600°C(2552°F kusvika 2912°F), izvo zvinoita kuti zvidimbu zveupfu zvibatane pamwe chete zvoita chinhu chakasimba, chakakora.

- Kubviswa kweBinder: Panguva yekusvina, cobalt binder inogadziriswawo. Inobatsira tungsten carbide particles kunamirana, asi mushure mekusvina, inobatsirawo kupa banga kuomarara kwaro kwekupedzisira uye kusimba.

- Kutonhodza: Mushure mekutsvaira, banga rinotonhodzwa zvishoma nezvishoma munzvimbo inodzorwa kudzivirira kutsemuka kana kukanganiswa.

4. Kukuya uye Kuumba

- Kukuya: Mushure mekutsvaira, banga rekabhoni rinowanzova rakakombama kana kuti risina kurongeka, saka rinogayiwa kuita zviyero chaizvo uchishandisa mavhiri emhando yepamusoro kana michina yekukuya. Danho iri rakakosha pakugadzira mupendero wakapinza uye kuona kuti banga rinosangana nezvinodiwa.

- Kuumba uye Kugadzira Profiling: Zvichienderana nekushandiswa, banga rinogona kuumbwa zvakanyanya kana kugadziridzwa. Izvi zvinogona kusanganisira kukuya makona chaiwo pamucheto wekucheka, kuisa machira, kana kugadzirisa chimiro chebanga racho.

5. Kupedza Kurapa

- Kuputira Pamusoro (Sarudzo): Mamwe mapanga ecarbide anowana mamwe marapirwo, akadai sekuputirwa kwezvinhu zvakaita setitanium nitride (TiN), kuti awedzere kuomarara, kuramba kupfeka, uye kuderedza kukweshana.

- Kupukuta: Kuti basa riwedzere kunaka, banga rinogona kukweshwa kuti rive pamusoro wakatsetseka, wapera unoderedza kukweshana uye unovandudza kushanda zvakanaka kwekucheka.

6. Kudzora Hunhu uye Kuedzwa

- Kuedzwa kweKuoma: Kuomarara kwebanga kunowanzo ongororwa kuti kuve nechokwadi chekuti rinozadzisa zvinodiwa, nemiedzo yakajairika inosanganisira kuyedzwa kwekuomarara kweRockwell kana Vickers.

- Kuongorora Kwemativi: Kunyatsorongeka kwakakosha, saka saizi yebanga inoongororwa kuti ive nechokwadi chekuti inosangana nezvinodiwa chaizvo.

- Kuedzwa Kwekushanda: Pamashandisirwo chaiwo, akadai sekucheka kana kuchekwa, banga rinogona kuongororwa kuti riite sezvakarongwa.

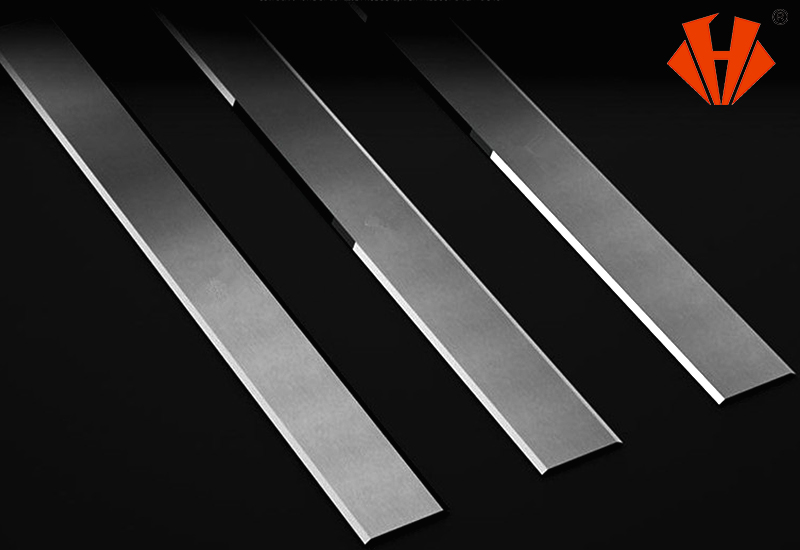

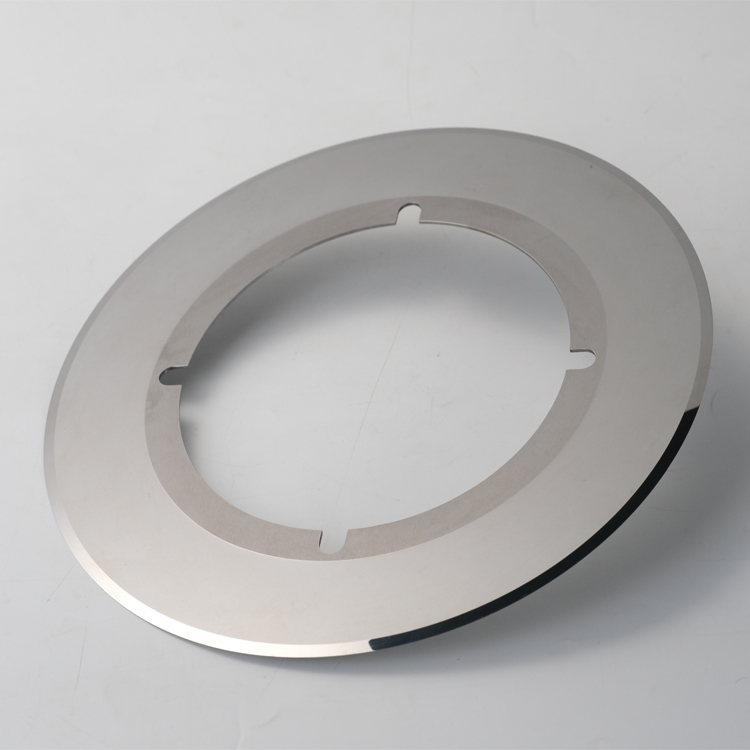

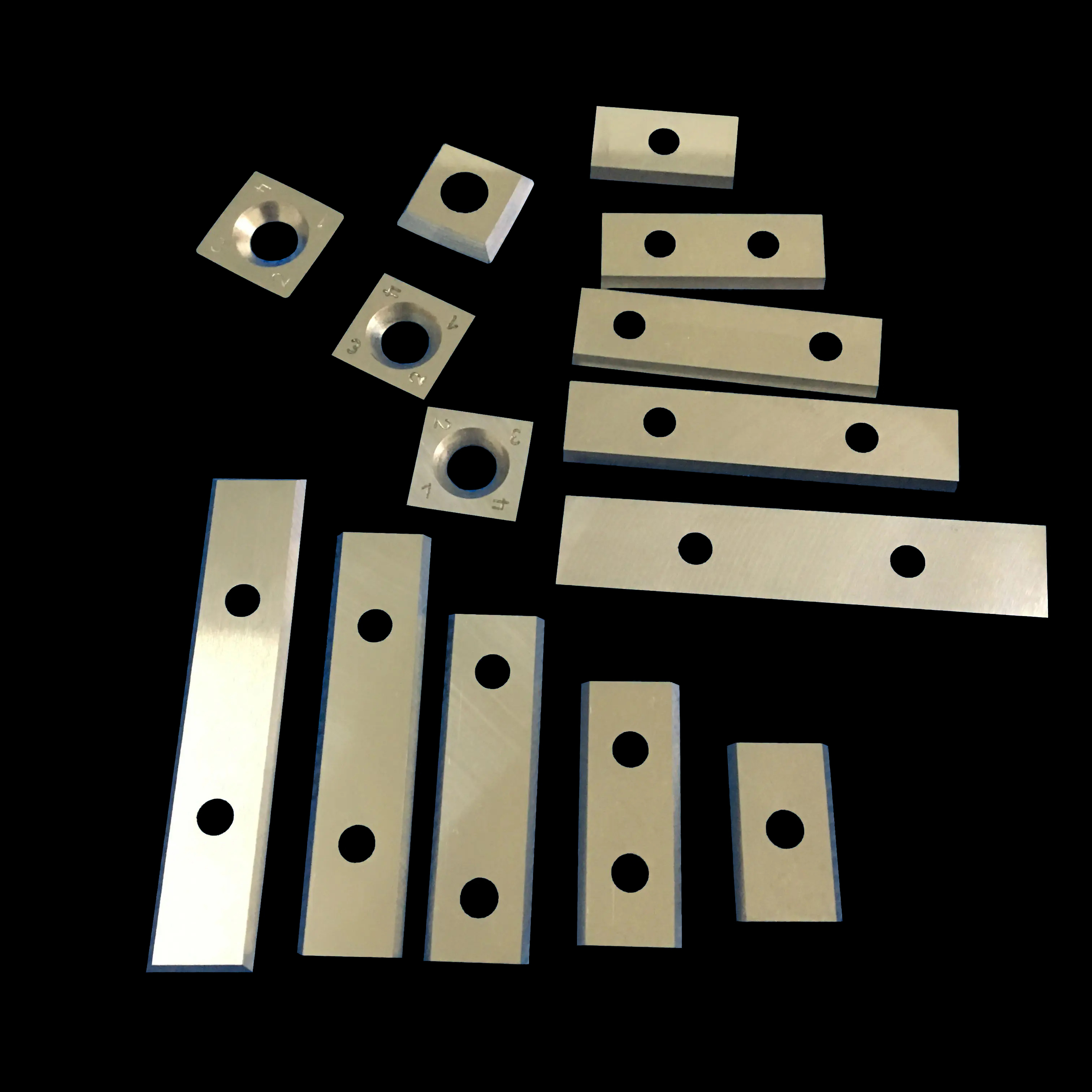

HUAXIN CARBIDE YAKASIMIDZWA inopa mapanga emhando yepamusoro e tungsten carbide nemablades kune vatengi vedu vanobva kumaindasitiri akasiyana pasi rese. Mablades anogona kugadzirwa kuti akwane michina inoshandiswa chero muindasitiri. Zvinhu zveblades, kureba kwemucheto uye maprofiles, marapirwo uye machira zvinogona kugadziriswa kuti zvishandiswe nezvinhu zvakawanda zveindasitiri.

Kana mapanga acho apedza kuongororwa kwemhando yepamusoro, anenge agadzirira kushandiswa mumaindasitiri akasiyana-siyana, akadai sekugadzira simbi, kurongedza, kana mamwe mabasa ekucheka uko kwakakosha kudzivirira kupfekwa kwakanyanya uye kupinza.

Nguva yekutumira: Mbudzi-25-2024